Have you ever looked at an EV and wondered what an EV battery is made of or how it works?

You are not alone.

Here, we examine what goes into making an EV battery, the different types, how they work, and what happens when they are recycled or repurposed.

When it comes to the structure of EV batteries, there are three basic types of cells: cylindrical cells, prismatic cells, and pouch cells.

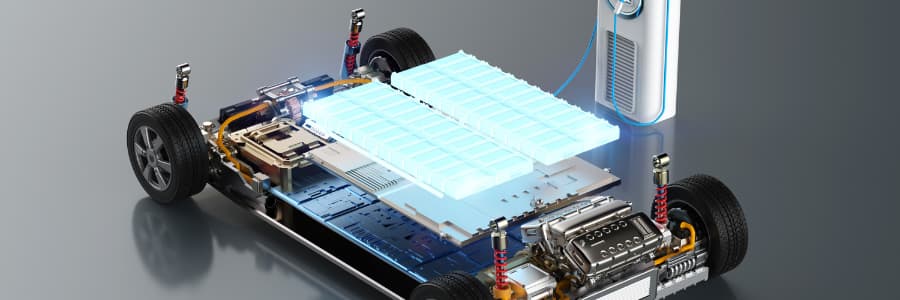

Electric car batteries are not a single unit but consist of hundreds of cells arranged in an array. This includes the cells mentioned previously, which are grouped into modules. These modules are then connected to form the final, full-sized battery pack (what most people commonly refer to when they say EV battery).

When talking about EV battery materials, we most often talk about the materials in and around the cells.

Nickel manganese cobalt (NMC) and nickel metal hydride (Ni-MH) were popular choices for EV battery cells early on but have since been replaced by other types.

Today, EV battery cells are often equated to lithium-ion. While this is the most common composite used today, there are others.

Briefly put, there are three types of batteries most commonly used in electric vehicles today:

Apart from the materials used, key components play central roles in making an EV battery:

An EV battery drives the vehicle’s engine and provides propulsion.

When you press the accelerator in an electric vehicle (EV), the battery discharges energy to power the motor. Lithium ions and electrons flow inside the battery from the anode to the cathode, creating an electric current. This current is sent to the motor, where it’s converted to momentum when the motor generates a rotating magnetic field that pulls the rotor, which in turn spins the gears and drives the vehicle’s wheels.

As the vehicle moves, the battery continues to supply energy, but the process changes when you release the accelerator. The motor, now acting as a generator, slows down the vehicle by converting the kinetic energy back into electrical energy, recharging the battery. This regenerative braking system allows the EV to recover some energy, improving efficiency and extending the driving range.

When EV batteries reach the end of their life, they can either be repurposed (for example, as energy storage units for renewable energy sources) or recycled.

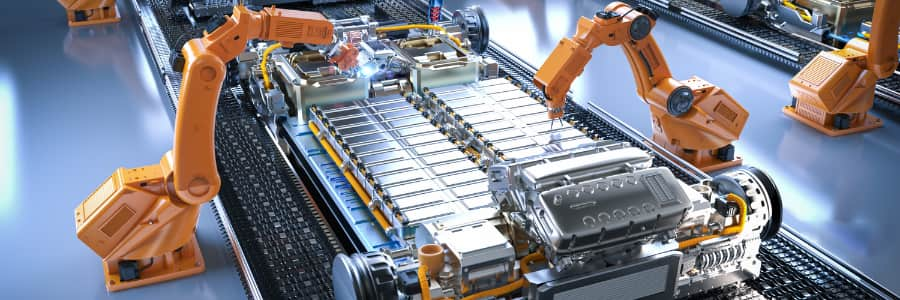

The recycling process includes collection and disassembly.

During disassembly, materials are recovered through techniques like sieving and magnetic separation. The recovered materials are then refined to remove impurities and prepare them for reuse.

Remaining waste or byproducts are managed and disposed of in ways that prevent or minimise environmental harm.

EV battery technology continues to improve. For example, ranges are increasing. For example, Mercedes-Benz recently re-broke the 1,000km (621 miles) on a single charge record with its VISION EQXX.

New materials and construction methods, such as solid-state batteries, are also appearing, promising to improve EV battery performance, making them more efficient and, in turn, using fewer raw materials.

Beyond materials, EV battery recycling is also improving and the amount of materials recovered for use in future EV batteries is steadily increasing.