Even when your EV has driven its last kilometre, it still has a life ahead of it; at least in parts.

Recycling electric vehicles (EVs) is, like the vehicles themselves, a relatively new phenomenon. However, it is gaining traction rapidly due to technological and economic advances.

The body or shell or an electric vehicle (EV) such as a Tesla often consists of metals and composites. This is similar to a combustion engine vehicle. At the end of the EVs operational life, recycling processes for the shell like those of traditional vehicles. However, there are nuances due to some different materials used.

Recycling processes typically involve shredding and then separating and recovering metals and other materials using magnetic and other advanced sorting technologies.

The metal can then be melted down and reused in the production of new vehicles or other products.

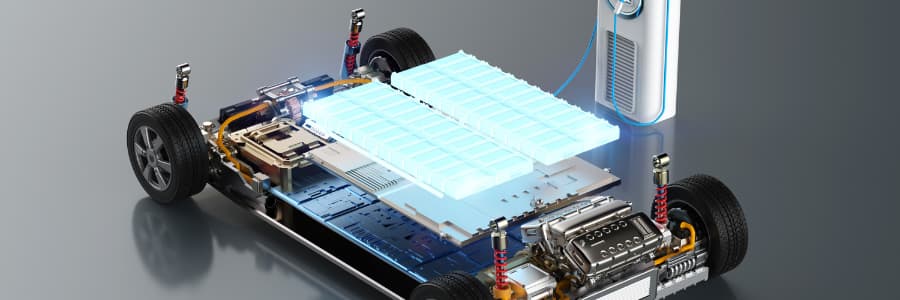

Recycling EV batteries, which are predominantly lithium-ion based, poses a different challenge. While the technology for recycling EV batteries exists, it is not yet widespread, primarily due to economic and technological limitations.

However, before reaching recycling, there are opportunities for EV battery reuse. One example is as energy storage for renewable energy systems. Similarly, EV batteries can be repurposed for less taxing use cases, such as powering golfcarts.

Many companies and research institutions are actively developing methods to assess and repurpose EV batteries and drivetrains more effectively. For recycling, various processes are being enhanced to recover valuable materials like lithium, cobalt, nickel, and manganese.

Previously, the cost of recycling could exceed the value of materials recovered, making it less attractive without regulatory or financial incentives. Additionally, the safety risks associated with handling and processing old batteries, could not be overlooked.

However, new solutions and the growth of EVs are rapidly changing this situation.

Like many other parts of the energy and mobility space, recycling all parts of EVs more effectively is advancing rapidly. One reason is that EV batteries are too valuable to throw away.

Simultaneously, the sheer number of EV batteries means an economy that coupled with new recycling methods, is spurring many companies to seek to address the waste problem and mitigate risks of battery material shortages.

EV battery recycling processes typically break the batteries down into three distinct component groups: plastics, metals, and black mass.

Black mass is basically a concoction of the minerals needed for new batteries. Retrieving them has been a complex, expensive and energy-intensive process.

However, researchers are finding new ways to recycle EV batteries that drastically cut costs and carbon emissions. In a similar vein, Nissan has found ways to recover high-purity rare-earth compounds from EV motor magnets.

The two examples above are just a couple of the many ongoing developments.

Others are working on making future EVs fully recyclable. For example, BMW has showcased its iVision Circular, which it says will be not only electric but 100% recyclable and manufactured almost entirely using materials sourced from the recycling loop.

A similar project called ZEvRA which aims to develop a “Circular Car Concept” is underway in the EU.

The project partners are looking to develop new vehicles made almost entirely from recycled parts by 2035.

Previously, the cost of recycling could exceed the value of materials recovered, making it less attractive without regulatory or financial incentives. Additionally, the safety risks associated with handling and processing old batteries, could not be overlooked.

However, new solutions and the growth of EVs are rapidly changing this situation.